Farewell to Quartz Dependence-Lithium Niobate Drives Dual Innovations in Materials and Structure for Trace Gas Detection

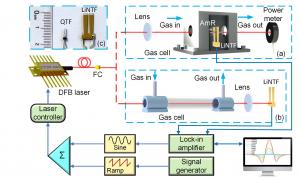

Figure 1. Schematic diagrams of the acetylene sensor; (a) C2H2-LiNPAS system; (b) C2H2-LITES system; (c) Schematic diagrams of the standard QTF and LiNTF.

Figure 2. (a) 2f signals of the C2H2-LiNPAS system based on LiNTF with and without AmR; (b) Noise of the standard QTF; (c) Noise of LiNTF without AmR; (d) Noise of LiNTF with AmR.

In this paper, a novel self-designed inverted-triangular lithium niobate tuning fork (LiNTF) was used to construct gas sensing system for the first time.

CHENGDU, SICHUAN, CHINA, January 6, 2026 /EINPresswire.com/ -- Trace gas detection technology is a widely used analytical method, applied in fields such as atmospheric monitoring, petrochemical industry, agricultural management, and medical diagnosis. Laser spectroscopy-based trace gas detection offers advantages including rapid response, high sensitivity, and low background noise, among which quartz-enhanced photoacoustic spectroscopy (QEPAS) and light-induced thermoelastic spectroscopy (LITES) are extensively utilized, with the quartz tuning fork (QTF) serving as the core detection component for both.However, commercial standard QTFs face significant performance bottlenecks: first, the weak piezoelectric coefficient and electromechanical coupling coefficient of quartz result in limited surface charge generation under the same stress; second, the inherent high resonant frequency (32768 Hz) of QTFs leads to a short energy accumulation time, restricting their trace detection capability; third, the structural shape of QTFs has a significant impact on surface charge quantity. Although studies have attempted to fabricate tuning forks using lithium niobate crystals, their detection performance has not met expectations with no significant difference from standard QTFs, due to single-electrode design, unoptimized structure, and excessively high resonant frequency. Therefore, there is an urgent need to design a high-performance lithium niobate tuning fork (LiNTF) to address the challenges in trace gas detection.

Professor Yufei Ma's team from Harbin Institute of Technology has proposed a novel gas sensing system based on a self-designed inverted triangular LiNTF. The tuning fork structure was optimized via finite element analysis to determine the optimal ratio of the upper and lower boundaries of the inverted triangular shape. This special structure concentrates the stress distribution of the tuning fork more at the root of the prongs, resulting in a surface charge density 12.6 times that of a standard QTF and a 2.3 times increase in stress value. Additionally, it boasts a high quality factor and a broad spectral range, significantly enhancing signal output capability.

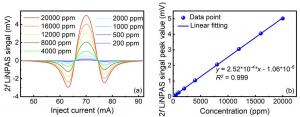

Two sensing systems constructed based on this tuning fork (Fig. 1) fully validated its technical advantages: In the lithium niobate-enhanced photoacoustic spectroscopy (LiNPAS) system, the 2f peak value and signal-to-noise ratio (SNR) of the inverted triangular lithium niobate tuning fork were 7.4 times and 5.9 times those of the standard QTF, respectively. After selecting an acoustic microresonator with optimal dimensions, the SNR was further improved by 56 times (Fig. 2), and it exhibited an excellent linear response (R²=0.999) in the concentration range of 200 ppm to 20000 ppm (Fig. 3); In the light-induced thermoelastic spectroscopy (LITES) system, the 2f peak value and SNR also reached 7.82 times and 6.03 times those of the QTF, respectively (Fig. 4).

About the Research Group:

Yufei Ma received his PhD degree in physical electronics from Harbin Institute of Technology, China, in 2013. From September 2010 to September 2011, he spent as a visiting scholar at Rice University, USA. Currently, he is a professor at Harbin Institute of Technology, China. He is an Optica Fellow and the winner of National Outstanding Youth Science Fund. His research interests include optical sensors, trace gas detection, laser spectroscopy, solid-state laser and optoelectronics. He has published more than 200 publications and given more than 40 invited presentations at international conferences.

Read the full article here: https://www.oejournal.org/oes/article/doi/10.29026/oes.2025.250035

Andrew Smith

Charlesworth Publishing Limited

+44 7753 374162

marketing@charlesworth-group.com

Visit us on social media:

LinkedIn

YouTube

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.